A new generation of batteries with sodium-sulfur technology

Theion aims to become a driving force in the energy transition

The limited availability and rising prices of materials used in conventional lithium-ion batteries means growing demands are becoming harder to meet. That is why Theion is working on developing a new generation of batteries based on sodium-sulfur technology. Establishing a sustainable production of alkali metal ion batteries at lower prices to drive the energy transition forward is the goal. For this, Theion is looking to sulfur for the cathode. It is readily available in large quantities and more cost-effective than conventional materials.

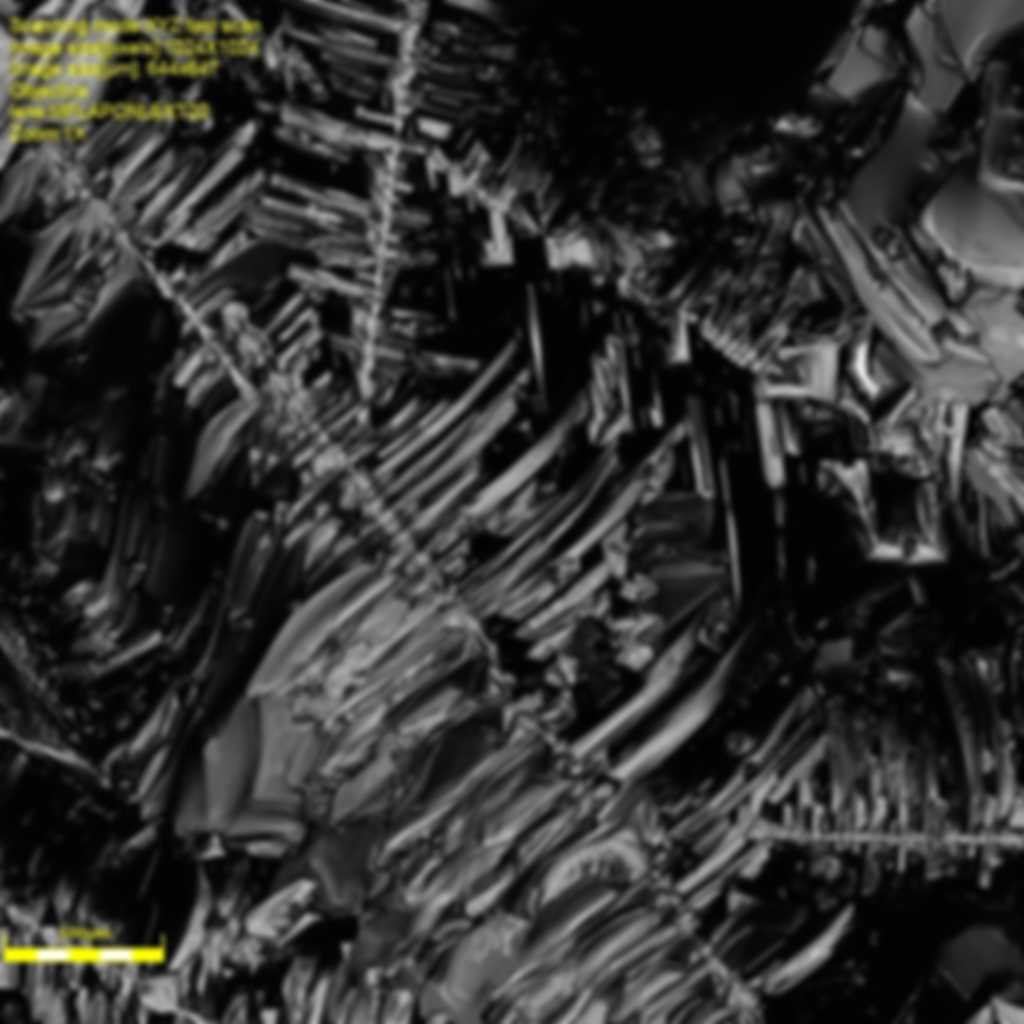

Sulfur batteries have the potential to store large amounts of energy in a small space. Thus, compared to conventional cathode materials, sulfur can theoretically store a significantly higher number of charge carriers. CSO and co-founder of theion Marek Slavik and his team have developed a technology that can efficiently utilize monolithic sulfur, and it is suitable for both lithium and sodium anodes. Plus, special coatings and processing techniques extend battery life.

SPRIND recently commissioned validation for sodium-sulfur batteries to specifically test its use in stationary storage. Sodium, found in household salt, is very cheap and available worldwide.

The company plans to set up large-scale production of its sulfur crystal batteries to meet rising market demand. Over the coming years, demand for battery cells for stationary and mobile applications is expected to boom. The team of 19 experts at Theion aims to meet those stationary battery needs with sodium-sulfur batteries, and it is also developing lithium-sulfur batteries for mobile applications. These batteries can achieve a high gravimetric energy density, increasing the range of electric vehicles and the flight time of eVTOLs (electric vertical take-off and landing vehicles) by a factor of two to three.

Marek Slavik explains: To harness the potential of the material combination of sodium and sulfur, we made a bold move to replace the standard electrode production process with an innovative, energy-saving one. These innovations are patented. We are happy that SPRIND has recognized the potential of our technology and awarded us the validation contract.

Inexpensive and clean mobile batteries will make electric mobility available for all income levels – on the ground and in the air,

adds Lukasz Gadowski, entrepreneur and Theion investor. Low-cost, household batteries mean clean electricity regardless of the weather or the size of your wallet, making it conceivable that 100 percent of the energy supply could eventually be CO₂-free. I have seen a lot of concepts, and I am convinced that investing my resources and creativity will be worthwhile at Theion.

The combination of Marek Slavik’s ingenious cell concept and Lukasz Gadowski’s visionary investment are the basis for the development of our innovative battery cells,

says CEO Dr. Ulrich Ehmes. With the help of the validation by SPRIND, we want to show that a new generation of batteries can be produced sustainably, at significantly lower costs, in Europe, and independently of Asian supply chains. Doing so, we can make the energy transition happen.

More about Theion: www.theion.de