9/28/2025

THE DREAM OF A BETTER WELD

How WeldNova enables a technological leap in the production of heavy industrial components

In our world, nothing works without a reliable infrastructure. Be it solid bridges for the railway, container ships for global trade or wind turbines for an independent energy supply, they all have one thing in common… Their manufacturing requires many kilometers of continuous welding. A steel wind turbine’s tower alone has a weld seam of about 700 meters for an average tower. In order to join such sheets, known in technical jargon as joining or welding, the same welding process has been used for about 90 years on a global scale.

Traditional submerged arc welding is a proven method, yet thick sheets require several layers of weld to be placed on top of each other. However, this multi-layer technique is time-consuming and costly due to the joint having to be filled with expensive additional materials. For a wind turbine tower comprising 25-millimeter-thick steel, this quickly amounts to six or more welding layers and around 100 hours of pure welding time. In addition, high CO₂ emissions are generated during the production of the filler materials.

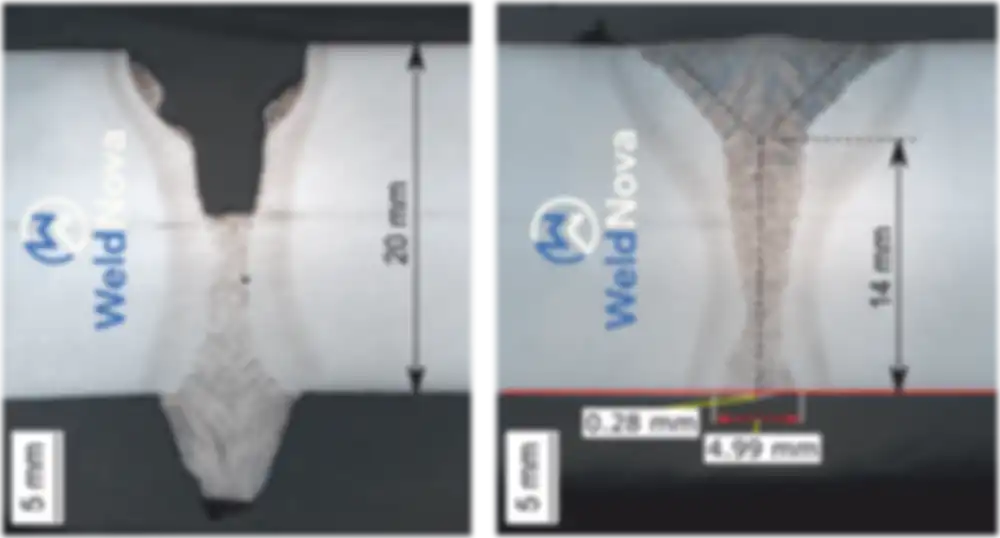

A fully automatable, energy-efficient and low-CO₂ alternative is laser beam welding. Laser beam welding has been established for decades for thinner sheet metal, for example, in the automotive industry. However, this highly efficient laser or laser hybrid welding technique cannot be used across the board in industry because the weld seams usually have insufficient quality or undesirable mechanical properties. The method reaches its limits when it comes to manufacturing tolerances such as varying gap sizes, edge offset or low edge quality. Above all, however, in the case of thicker components over ten millimeters thick, the molten material drips downwards from the weld joint due to gravity. As a result, laser or laser hybrid welding is technologically more advanced, but the technology cannot yet be controlled as well as submerged arc welding.

WeldNova has developed a technology to counteract gravity. With the help of oscillating magnetic fields, the melt is held in suspension. In addition, the quality criteria of the melt can be manipulated during the welding process, i.e., shaped or stirred. Their technology, which they call WeldMagnet, enables the use of laser welding on thick sheet metal for the first time – and in a single welding pass without several layers. This means that uneven edges or gaps of up to two millimeters can even be welded safely and without defect. Sheets of up to 40-millimeters thickness could be welded single-layer on one side using a laser beam – without the time-consuming preparation of the joint or many layers of welding wire. This is unique in the world. For example, the production of steel towers for wind turbines can be significantly improved: An eight- to ten-fold productivity increase is possible alongside an additional welding cost reduction of over 90 percent. At the same time, considerable amounts of energy and more than 90 percent indirect CO₂ emissions are saved.

The core WeldNova team comprises four experienced scientists from the field of welding technology. Ömer Üstündağ is responsible for the application development of the technology, Nasim Bakir for product development and Fatma Akyel for R&D. Managing Director Christian Brunner-Schwer is responsible for sales. The company is a spin-off of the Federal Institute for Materials Research and Testing.

SPRIND is testing the technology as part of a validation order with a specific area of application: 30 millimeters is a typical sheet thickness in the construction of onshore wind turbines. Tests are being carried out to determine whether the technology can be transferred to this sheet thickness for longitudinal and circular seams. All of the mechanical-technological weld seam properties are additionally being examined as fatigue strength, in particular, is part of the qualification process due to continuous exposure of the components to dynamic loads.

More about WeldNova